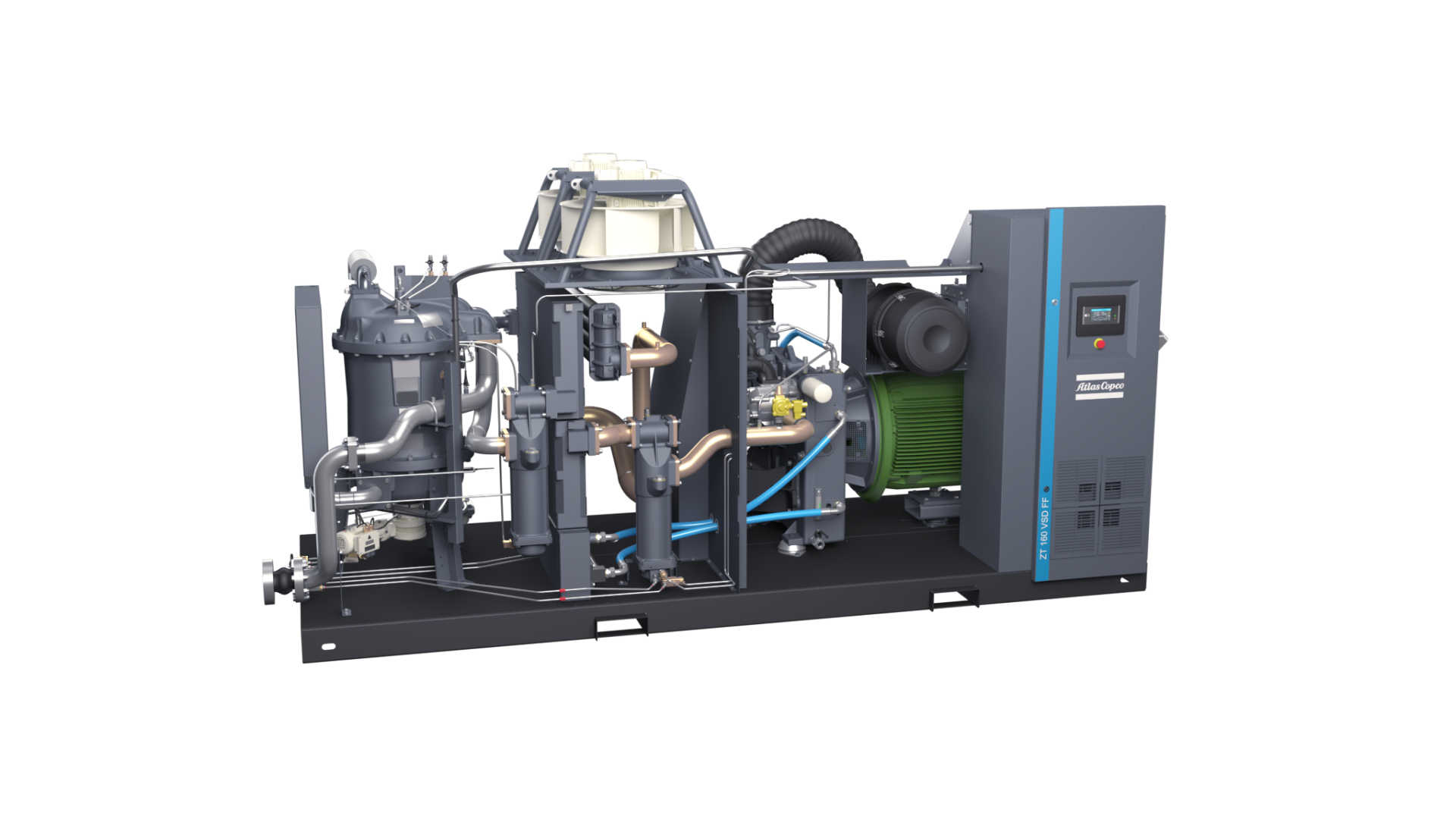

Design & control algorithms for optimal efficiency

Components designed for efficiency

- Compressor elements with superior coating, optimized design and low loss bearings and seals ensure highest efficiency.

- Efficient intake filtration for minimum losses and low pressure drop.

- Coolers are designed for efficiency with low pressure drop and low air approach temperature, ensuring coolest possible running conditions.

- Our fixed speed machines come with IE4 super premium efficiency motors, giving you extra energy savings, every hour the machine runs.

- VSD machines are equipped with IE3 premium efficiency motors, in combination with our highly efficient in-house designed Neos frequency converter.

- With machines typically running 4000 to 8000 hours per year, again a major contributor to energy savings.

Lower energy costs with Atlas Copco’s VSD technology

Over 80% of a compressor’s lifecycle cost is taken up by the energy it consumes. Moreover, the generation of compressed air can account for more than 40% of a plant’s total electricity bill. To cut your energy costs, Atlas Copco pioneered Variable Speed Drive (VSD) technology in the compressed air industry. VSD leads to major energy savings, while protecting the environment for future generations. Thanks to continual investments in this technology, Atlas Copco offers the widest range of integrated VSD compressors on the market.

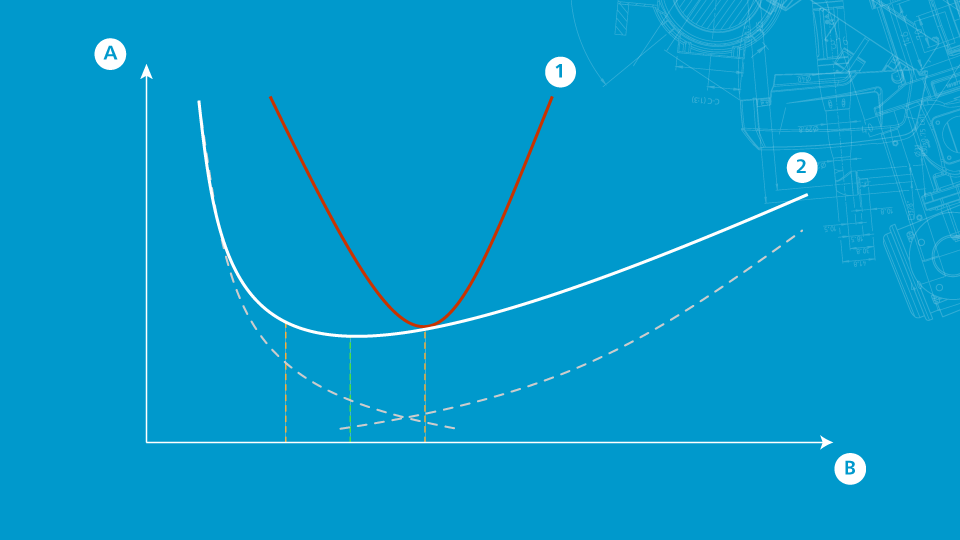

Legend

A = Losses

B = Speed

1 = Total losses traditional element

2 = Total losses Atlas Copco element

Up to 35% energy savings

Atlas Copco’s VSD technology closely follows the air demand by automatically adjusting the motor speed. This results in large energy savings of up to 35%. The Life Cycle Cost of a compressor can be cut by an average of 22%. In addition, lowered system pressure with VSD minimizes energy use across your production dramatically.

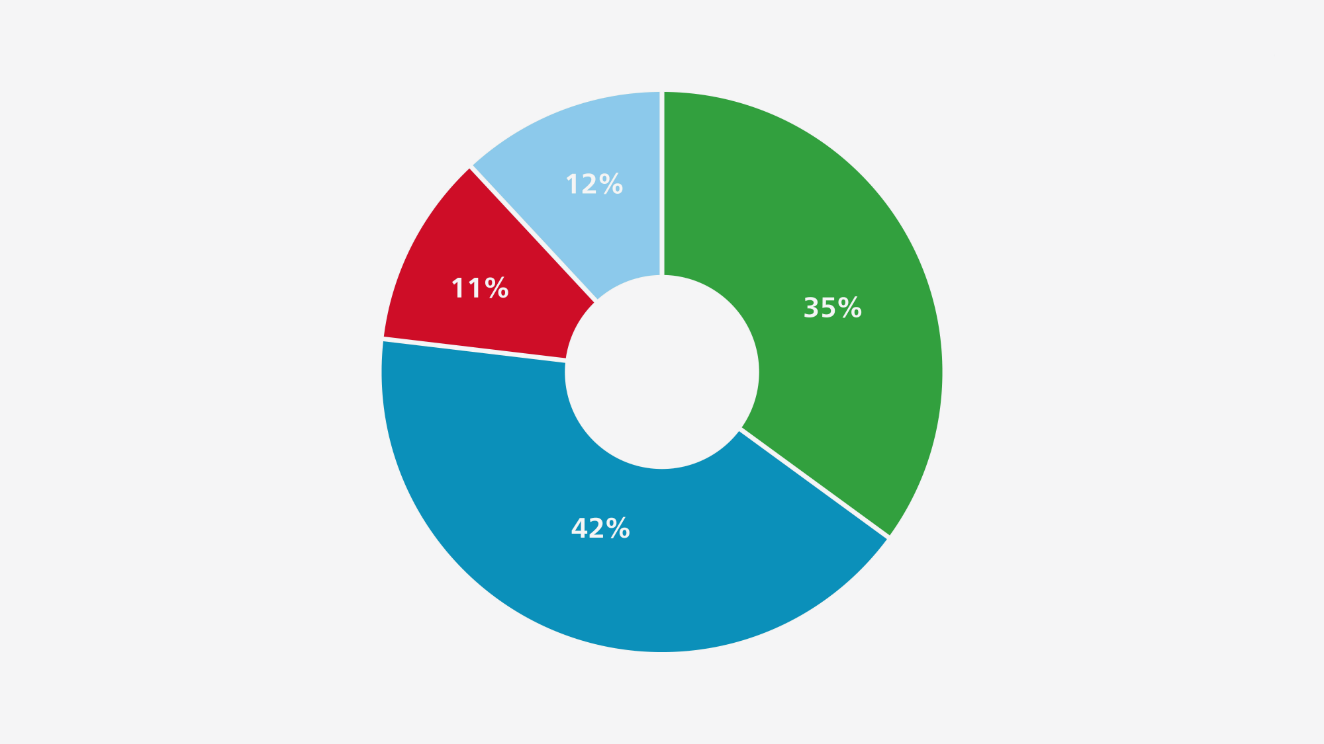

Legend

42% = Energy

35% = Energy savings with VSD

12% = Investment

11% = Maintenance

Monitor your compressed air installation with SMARTLINK

Knowing the status of your compressed air equipment at all times is the surest way to achieve optimal efficiency and maximum availability.

Go for energy efficiency

Customized reports on the energy efficiency of your compressor room.

Increase uptime

All components are replaced on time, ensuring maximum uptime.

Save money

Early warnings avoid breakdowns and production loss.

Energy Recovery

You can turn your compressor into an energy source. Our ZR compressors equipped with Energy Recovery can help you achieve your goals in becoming carbon neutral. Compressed air is one of the most important utilities for the industry. It is also one of the largest consumers of energy. Up to 94% of the electrical energy is converted into compression heat. Without energy recovery, this heat is lost into the atmosphere via the cooling system and radiation. You can use hot water recovered from the compressed air system for sanitary purposes and space heating. But it is particularly suitable for process applications. Using the hot water as boiler pre-feed or directly in processes requiring 70 to 90°C can save you costly energy sources such as natural gas and heating oil.

Advanced control algorithms

The Elektronikon compressor monitoring system saves energy by using advanced control algorithms:

Delayed Second Stop (DSS): in traditional fixed speed machines (load/unload), when a compressor reaches the unload pressure, the machine will be kept running in unload for a fixed time, to prevent too frequent starting and causing the electrical motor to overheat. Our sophisticated Delayed Second Stop (DSS) will take the running conditions of the machine into account and will allow the machine to stop if no frequent motor starts preceded. This will generate major savings compared to traditional load/unload compressors.

Timer functions: stop your machines when no air is needed. Often, machines are kept running over night and during weekends, even if there is no need for compressed air during these times. The timer function on our compressors can easily fix this.

Dual pressure band: even if compressed air is needed during nights and weekends, often, the required pressure is lower during these times. Implementing a dual pressure band with lower settings during nights and weekends will save loads of energy.

Dual set-point and automatic stop

Most production processes create fluctuating levels of demand which, in turn, can create energy waste in low use periods. Using the Elektronikon® unit controller, you can manually or automatically switch between two different setpoints to optimize energy use and reduce costs at low use times. In addition, the sophisticated algorithm runs the drive motor only when needed. As the desired setpoint is maintained while the drive motor’s run time is minimized, energy consumption is kept to a minimum.

Multiple machine control

Any installation with three or more machines will benefit from our advanced controller, the Optimizer 4.0. It will control your installation in a more efficient way than the individual machines with individual settings can.