To ensure the success of your business, you need to guarantee consistent quality while minimizing your overheads. A ZR/ZT 30-55 FLX compressor keeps you on track by delivering a reliable supply of clean, dry air with the lowest possible energy consumption for your operation. To cut running costs even further, every component is optimized for long life and easy servicing.

Engineered to enhance your profits

ZT 30-55 FLX iD FF

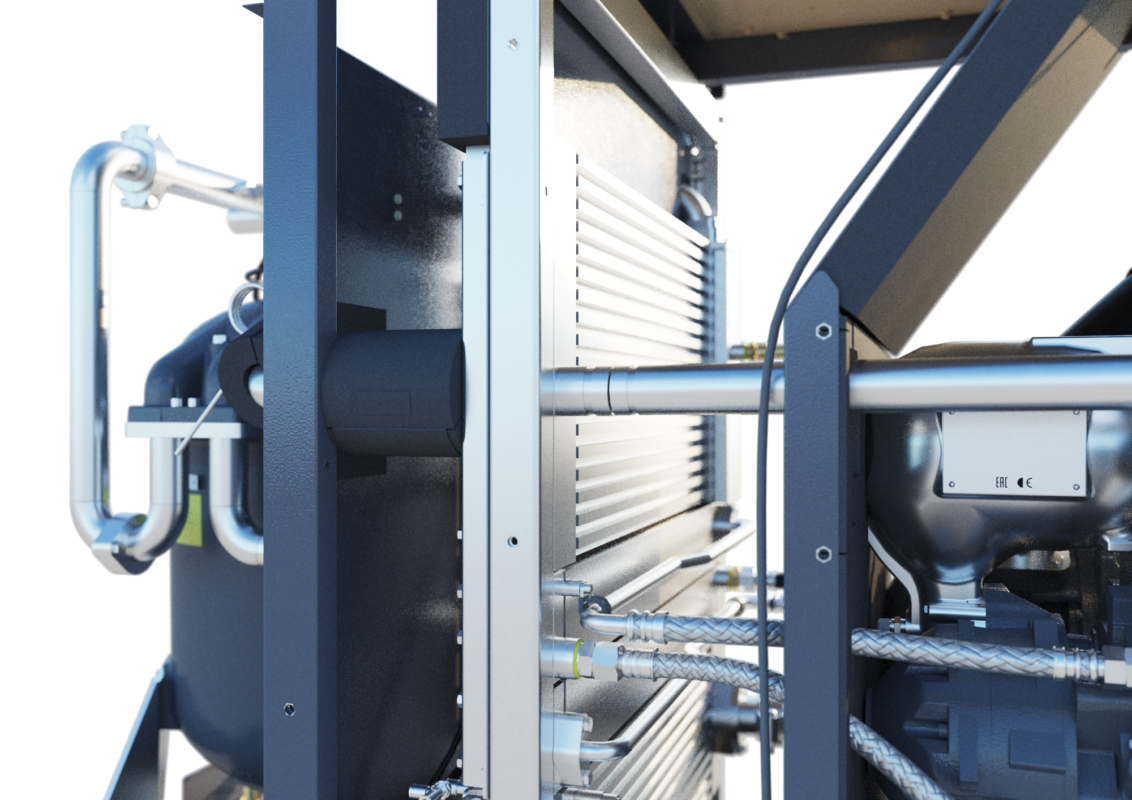

ZT 30-55 FLX FF Front Interior Element Highlights

ZT 30-55 FLX FF Back Interior Element Highlights

-

1

Advanced Elektronikon® monitoring system

-

2

Compact design

-

3

NEOS Next frequency converters

-

4

Soundproof canopy

-

5

Permanent Magnet Motors

-

6

Oil-free tooth element

-

7

Reliable cooling

-

8

Low maintenance

-

9

Integrated dryer

-

Advanced Elektronikon® monitoring system

– Touch screen operating system with numerous control and monitoring features

– Embedded control algorithms enhance efficiency and reliability

-

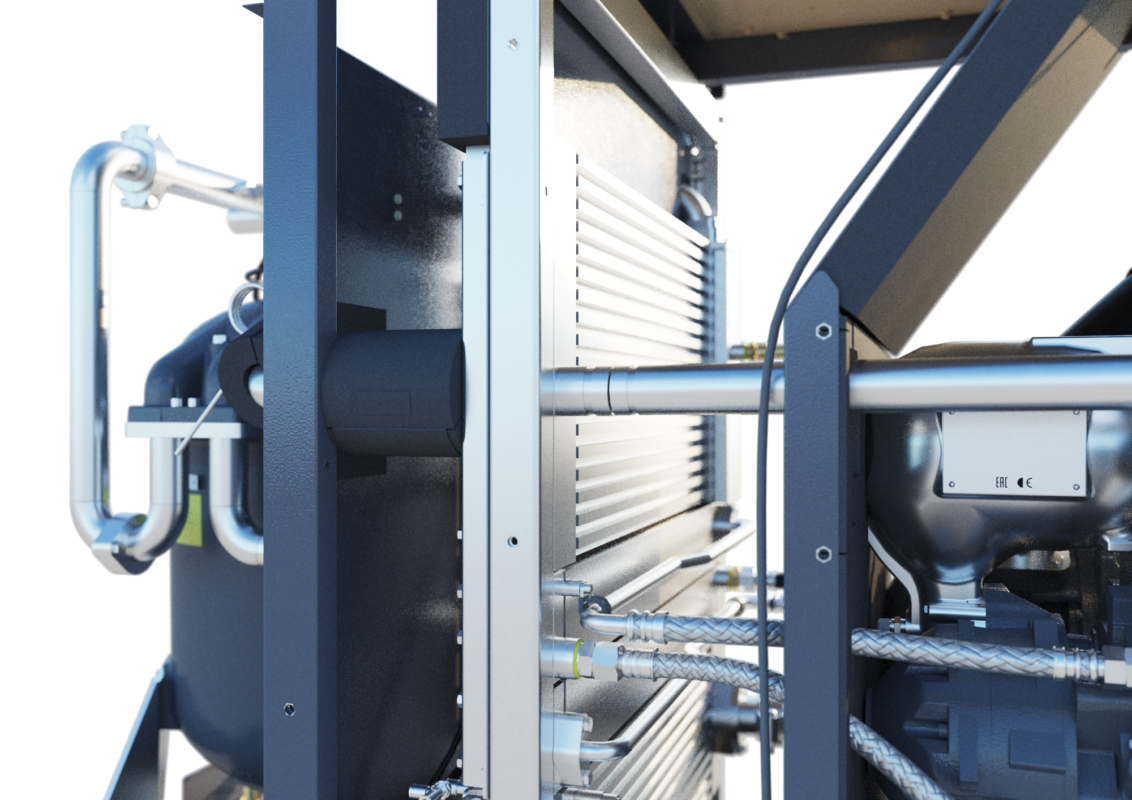

Compact design

– Designed to have the smallest possible footprint

– The Pack version without integrated dryer is the most compact of all

– The Full Feature version with integrated ID refrigerant dryer and IMD rotary drum dryer saves considerable space and installation work compared to similar freestanding dryers

-

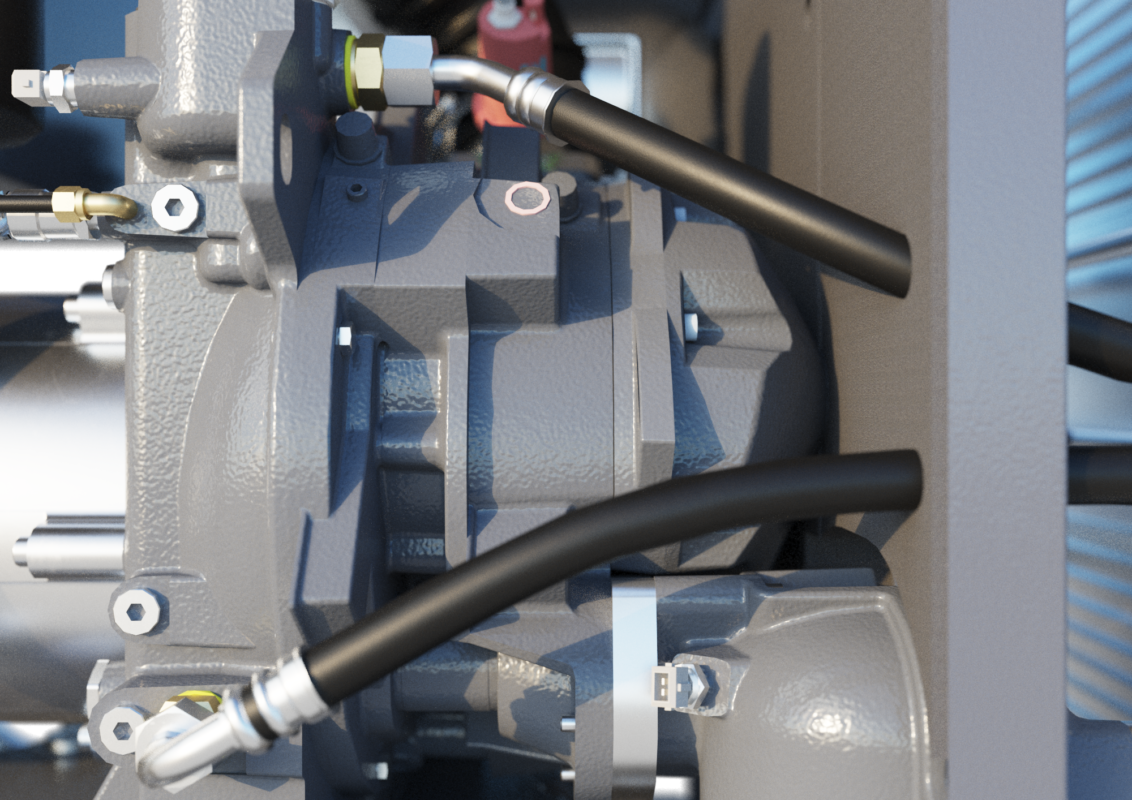

NEOS Next frequency converters

– In-house designed NEOS Next frequency converters ensure stable operation up to 50°C/122°F

– IP54 grade protection for reliability even in harsh conditions

– NEOS Next contains the main frequency drive for the drive motor plus an auxiliary drive for the cooling fan and dryer

– Two NEOS Next frequency converters are combined with two IE5 ultra-premium efficient permanent magnet motors to optimize load distribution at every running condition

– ZT 30-55 FLX compressors can range between 28 and 100% of their maximum capacity (turn down 72%), ensuring stable net pressures and maximum energy savings

-

Soundproof canopy

– Sound insulation allows for installation in most working environments

– No need for a separate compressor room

-

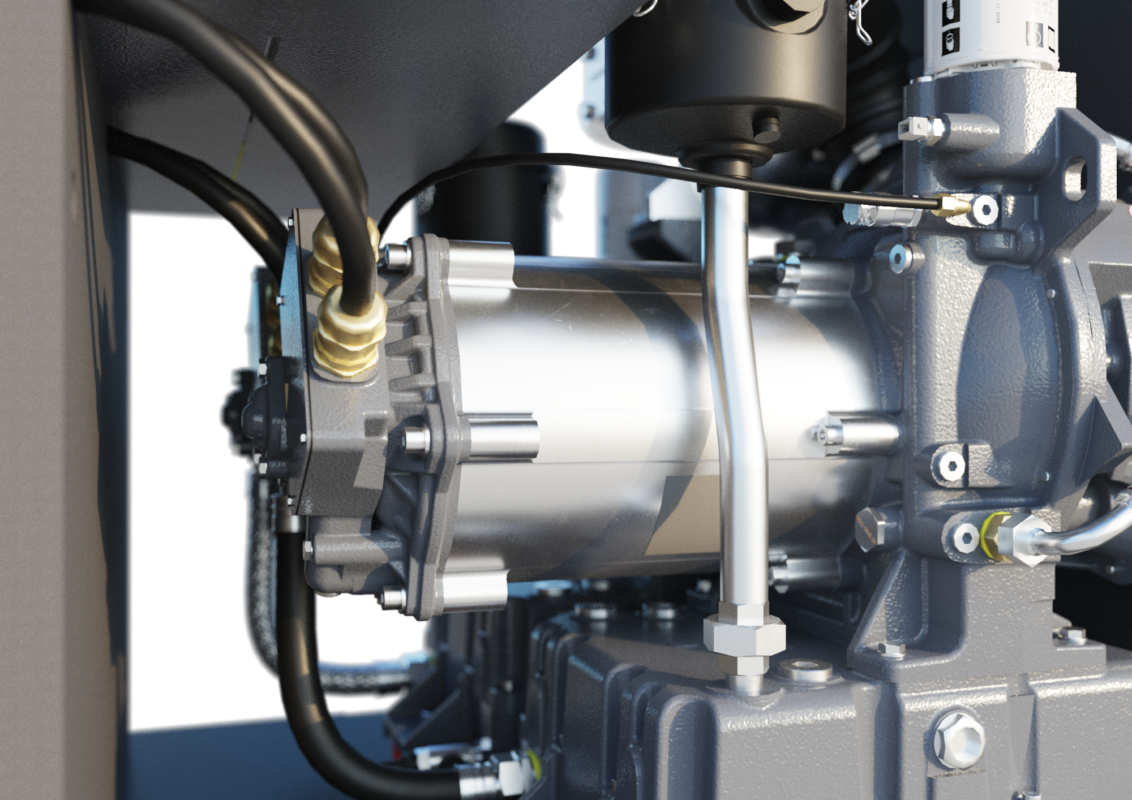

Permanent Magnet Motors

– Selection of permanent magnet motors allows ZR/ZT FLX to reduce rpms during unload state enabling significant savings.

– A proven design with a direct coupled permanent magnet drive motor for low- and high-pressure element, each with their own frequency converter

– Oil cooled permanent magnet motors with IP66 protection grade that have stood the test of time in other product ranges in real field conditions

– Optimization of intercooler pressure for the complete speed range. That is premium reliability combined with premium efficiency.

-

Oil-free tooth element

– Proven reliability and durability

– Most efficient element in this power range of oil-free compressors

-

Reliable cooling

– Available in both air-cooled and water-cooled versions

– Frequency-controlled fan optimizes cooling for all running conditions

– Oil cooling shields permanent magnet motors from the environment and makes them more robust

-

Low maintenance

– Components strategically placed for ease of access

– Oil-lubricated motor bearings do not require re-greasing

-

Integrated dryer

– With integrated dryer option , helping save on footprint and installation costs.

– Available in both Refrigerant and Heat of Compression versions,

– With Heat of Compression option providing dew point suppression of more than 30°C/86°F.

ZT 30-55 FLX Pack

ZT 30-55 FLX Pack Front Interior Element Highlights

ZT 30-55 FLX Pack Back Interior Element Highlights

-

1

Advanced Elektronikon® monitoring system

-

2

Compact design

-

3

NEOS Next frequency converters

-

4

Soundproof canopy

-

5

Permanent magnet motor

-

6

Oil-free tooth element

-

7

Reliable cooling

-

8

Low maintenance

-

Advanced Elektronikon® monitoring system

– Touch screen operating system with numerous control and monitoring features

– Embedded control algorithms enhance efficiency and reliability

-

Compact design

– Designed to have the smallest possible footprint

– The Pack version without integrated dryer is the most compact of all

– The Full Feature version with integrated ID refrigerant dryer and IMD rotary drum dryer saves considerable space and installation work compared to similar freestanding dryers

-

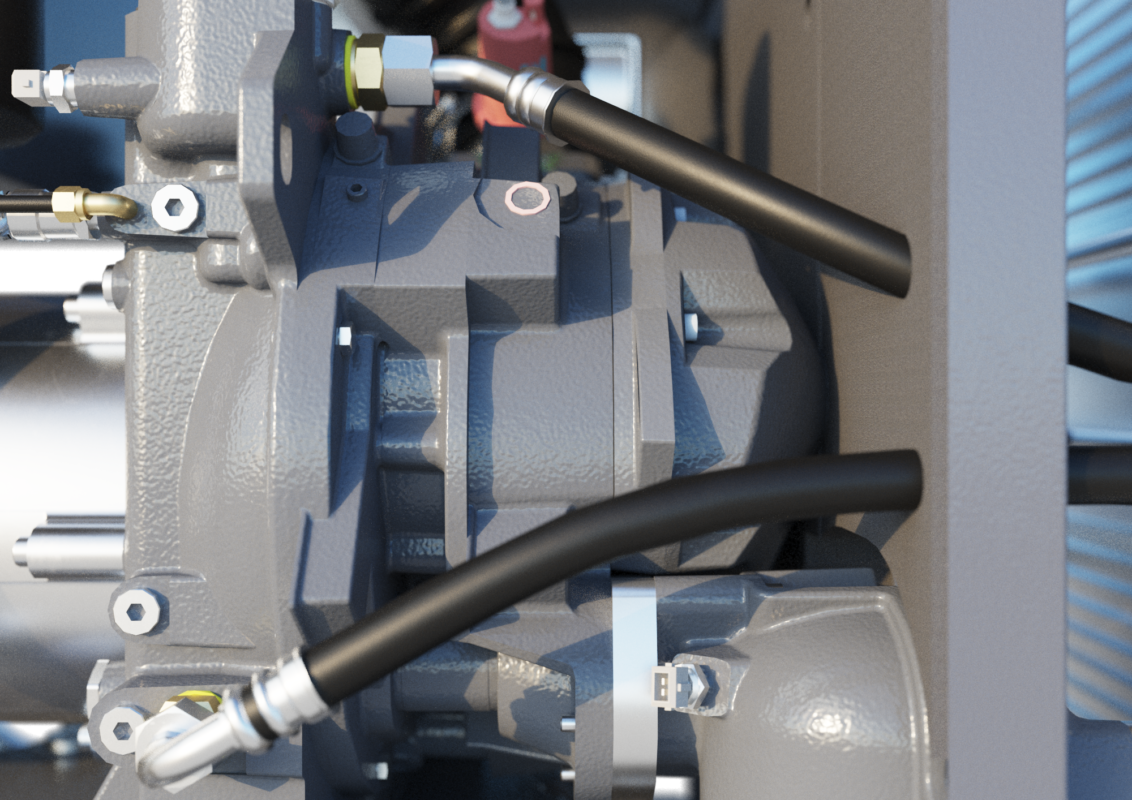

NEOS Next frequency converters

– In-house designed NEOS powers the ZR/ZT 30-55 FLX , allowing the unit to run at minimum speed during unload, reducing the unload power consumption to minimum.

– With VSD license enabled , your FLX is able to run anywhere between maximum and 30% of its capacity , allowing unmatched flexibility.

– NEOS Next is designed to withstand temperatures up to 50°C/122°F.

-

Soundproof canopy

Sound insulation allows for installation in most working environments. No need for a separate compressor room.

-

Permanent magnet motor

– Selection of permanent magnet motors allows ZR/ZT FLX to reduce rpms during unload state enabling significant savings.

– A proven design with a direct coupled permanent magnet drive motor for low- and high-pressure element, each with their own frequency converter

– Oil cooled permanent magnet motors with IP66 protection grade that have stood the test of time in other product ranges in real field conditions

– Optimization of intercooler pressure for the complete speed range. That is premium reliability combined with premium efficiency.

-

Oil-free tooth element

– Proven reliability and durability

– Most efficient element in this power range of oil-free compressors

-

Reliable cooling

– Air-cooled oil coolers, intercooler, and aftercooler

– Frequency-controlled fan optimizes cooling for all running conditions

– Oil cooling shields permanent magnet motors from the environment and makes them more robust

-

Low maintenance

– Components strategically placed for ease of access

– Oil-lubricated motor bearings do not require re-greasing