Did you know that compressed air generation can amount to over 40% of a plant’s total electricity bill? And that energy consumption can account for over 80% of a compressor’s lifecycle cost? For businesses serious about increasing their profits, energy consumption is an obvious target. It was therefore one of the leading design priorities of Atlas Copco.

Building energy savings into your process

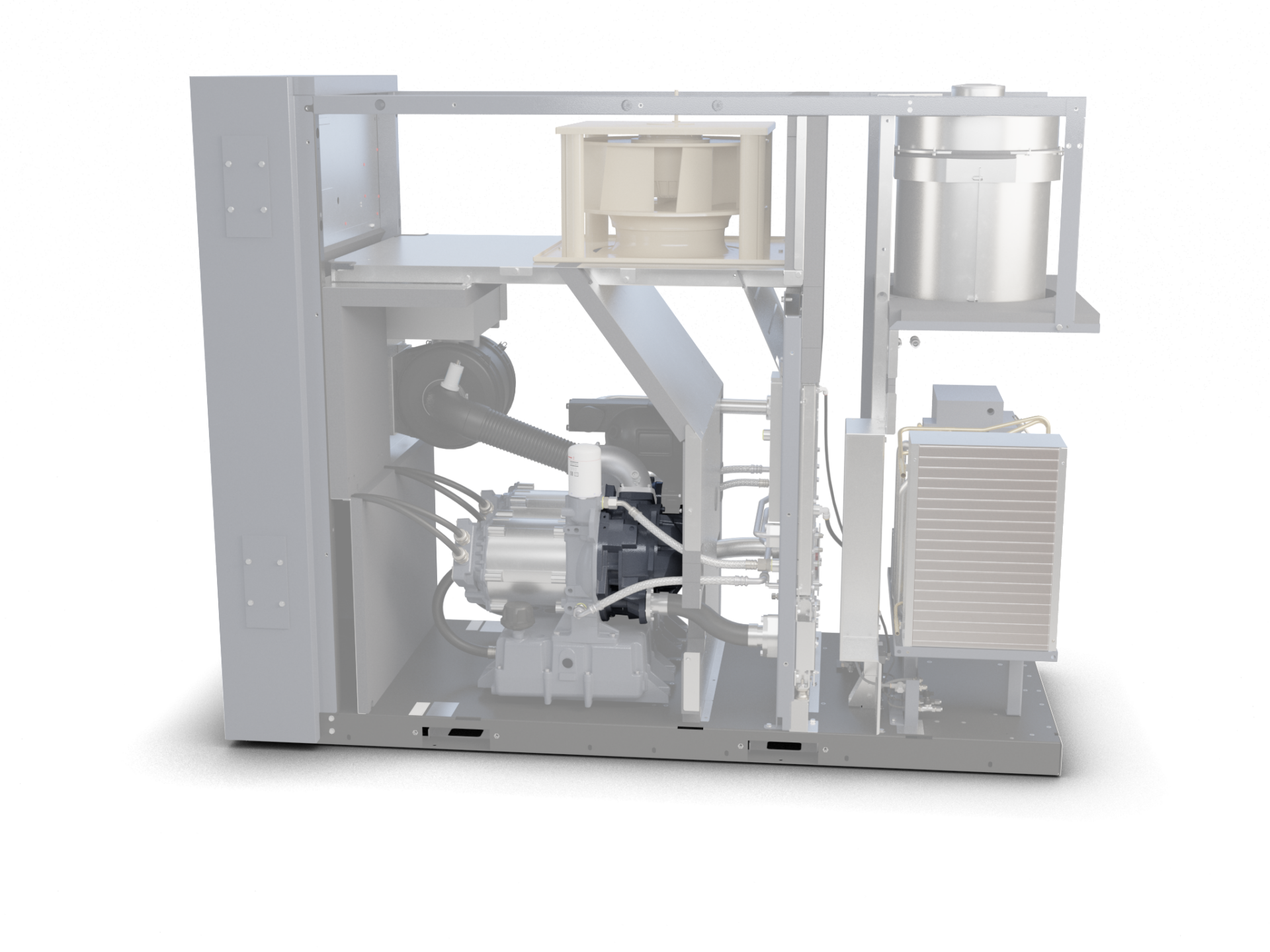

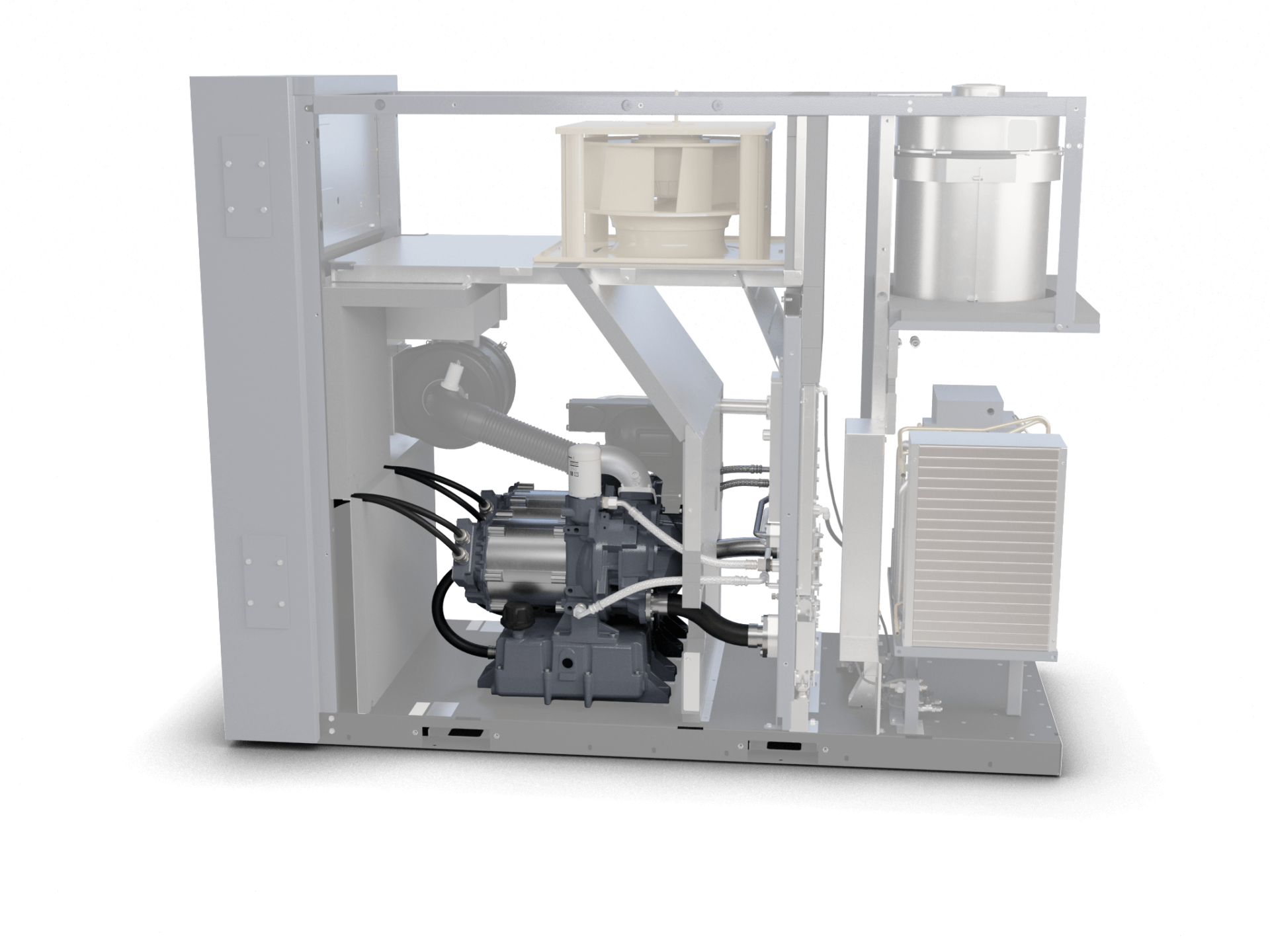

Energy-saving componentsOur engineers took every opportunity to reduce energy consumption in these machines. The patented elements are designed in-house for maximum efficiency. A superior coating on the active surfaces of the stainless steel rotors contributes to the most efficient oil-free tooth technology in this capacity range. A unique Z seal design further reduces running costs and guarantees 100% certified oil-free air for your application.  Oil-free Tooth Element– In-house designed.  Motor– IP66 oil-cooled Permanent Magnet Motor with oil-lubricated bearings.  Neos Next– Exceptional piece of engineering, developed in-house , allowing the unit to run at minimum speed during unload, reducing the unload power consumption to minimum.  VSD cooling fansThe completely redesigned cooling air flow supported by a VSD cooling fan ensures maximum energy savings during unload.  Plug & play– Integrated rotary drum dryer option (iMD) for moisture sensitive applications. |

Optimized air flow

The ZT 30-55 FLX brings cool, dense air into the package for optimal compression efficiency. Carefully designed coolers and strategically positioned piping and components minimize pressure drop in the package, while zero-loss drains ensure that no compressed air is wasted.

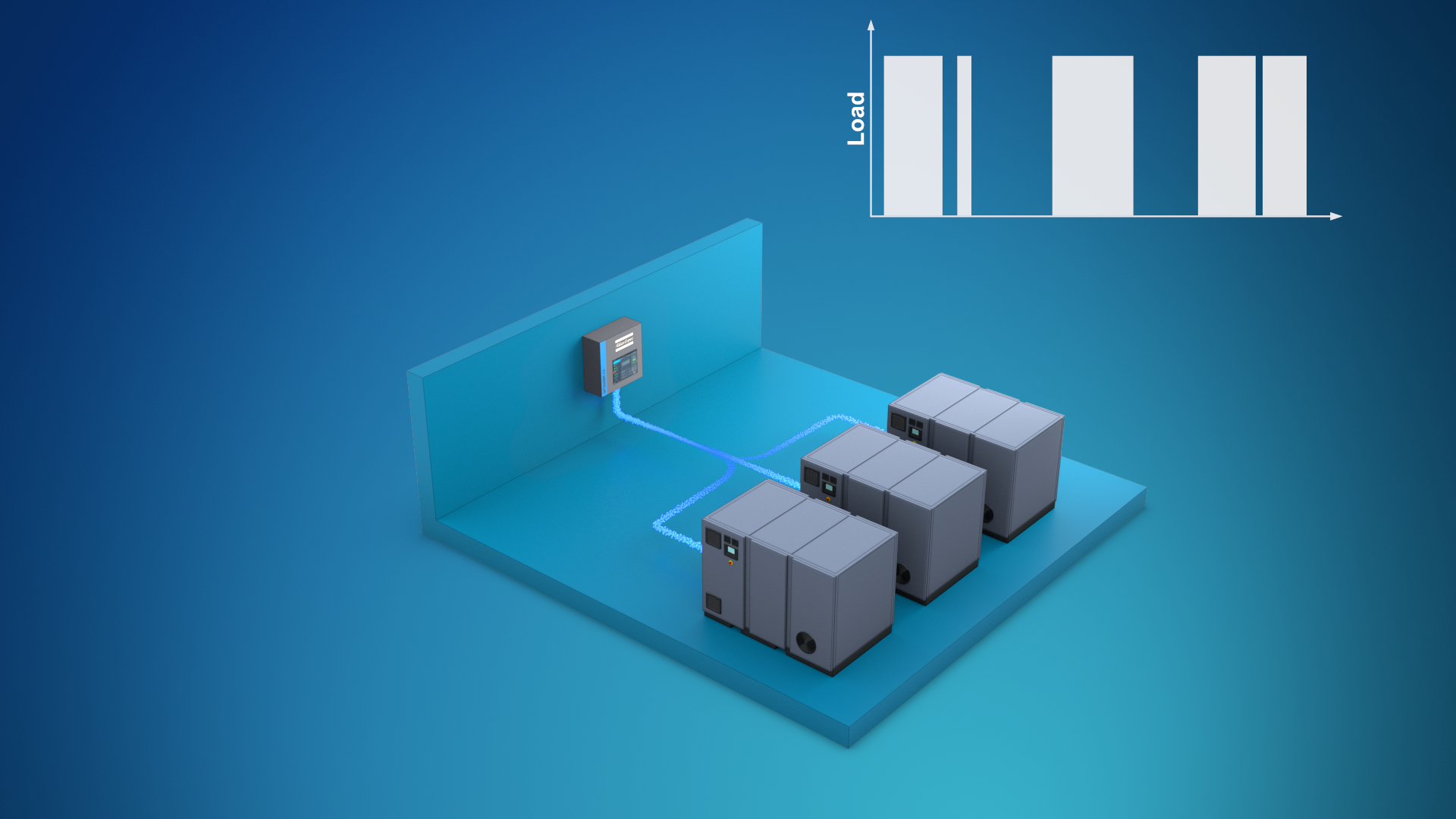

Advanced control algorithms

Advanced algorithms control your equipment to save energy when demand is low. For example, timer functions can stop your machines at night and during the weekend if no compressed air is needed. Alternatively, a dual pressure band can be implemented with lower pressure settings for these periods.