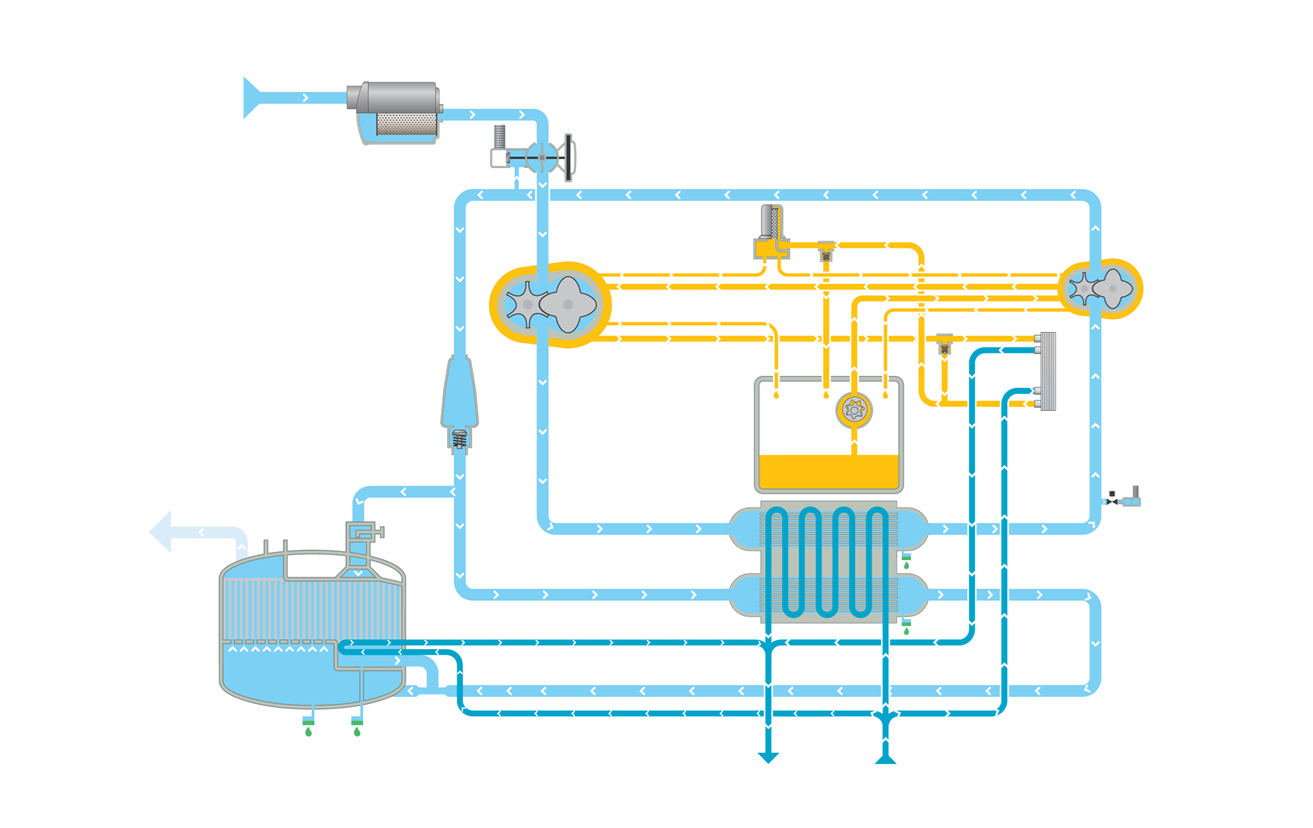

Oil and air flows: water-cooled (ZR)

Filtration & first compression

The light blue flow represents the air. Air is drawn into the compressor through the inlet filter, where the air is cleaned. It then passes through the throttle valve with integrated blow off valve, which takes care of the load/unload regulation.

In the first compression stage the air pressure is raised to the intermediate pressure, after which the air is cooled down in the intercooler.

Cooling & second compression

After the intercooler, the air passes through a moisture separation system before entering the high pressure stage. In the high pressure stage the pressure is brought to the final pressure.

Cooling & drying

The air at the outlet of the high pressure stage is split into two parts. One part goes via the pulsation damper with integrated check valve to the aftercooler, where it is cooled down and moisture is separated and evacuated. A second part goes directly to the regeneration area of the heat compression MD dryer.

In the regeneration area of the dryer, the hot air regenerates the adsorption drum before passing through the regeneration cooler where it is cooled down and moisture is separated and evacuated. The cold air coming from the regeneration section is then mixed with the cold air from the aftercooler in the nozzle ejector system before passing through the drying section of the adsorption drum where the moisture is removed. Dry air leaves the compressor through the outlet connection flanges.

Oil flow

The yellow flow is the oil path within the compressor. The oil pump sucks oil from the oil sump and pumps it through the oil cooler and a high efficiency filter to deliver cool, clean oil to the bearings and the gears. The oil then flows back to the gear casing.

Water flow

The dark blue flow represents the water. Water is used in the oil cooler, the intercooler, and the aftercooler, as well as in the integrated dryer.

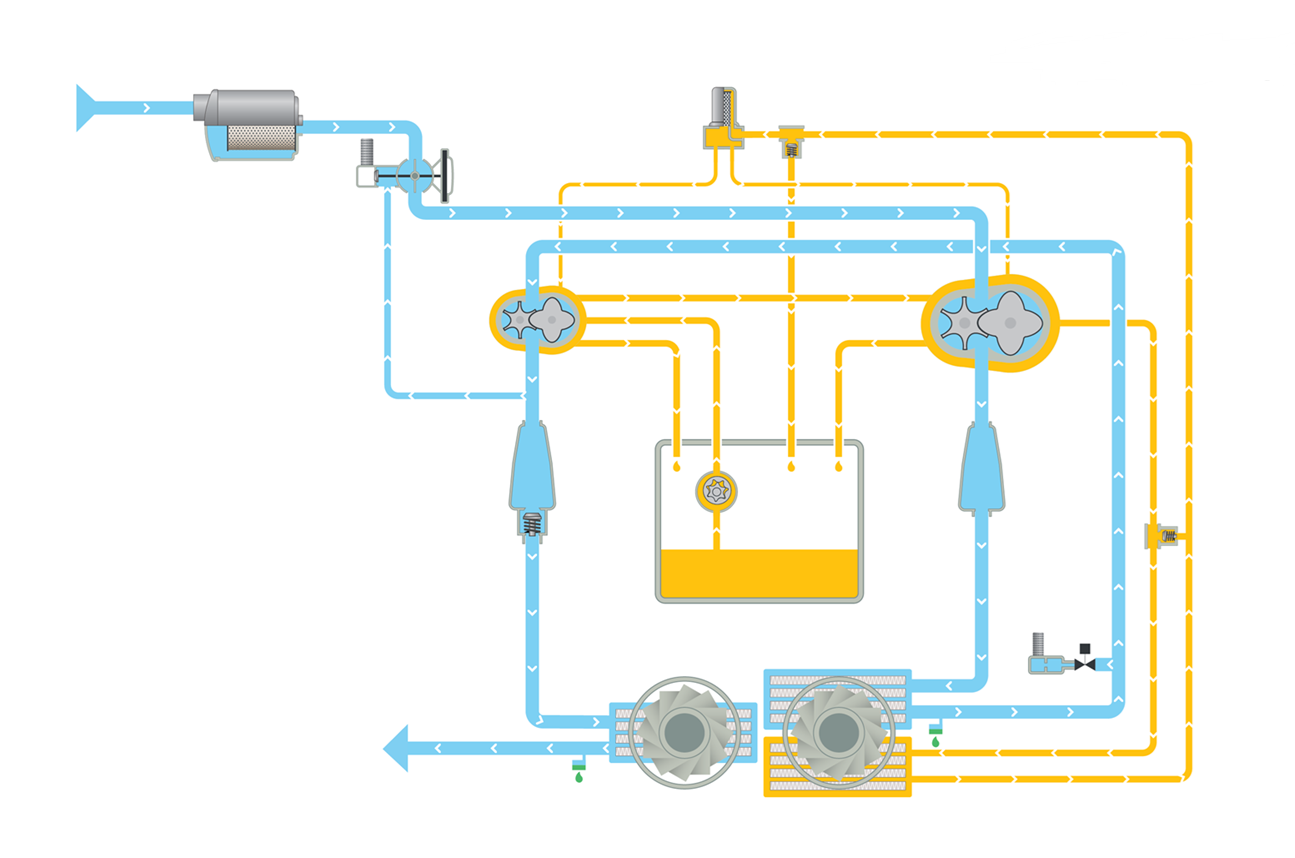

Oil and air flows: air-cooled (ZT)

Filtration & first compression

The light blue flow represents the air. Air is drawn into the compressor through the inlet filter, where it is cleaned. It then passes through the throttle valve with integrated blow off valve, which takes care of the load/unload regulation.

In the first compression stage the air pressure is raised to the intermediate pressure, after which the air is cooled down in the intercooler.

Cooling & second compression

After the intercooler, the air passes through a moisture separation system before entering the high pressure stage. In the high pressure stage the pressure is brought to the final pressure.

Cooling & drying

The air at the outlet of the high pressure stage is split into two parts. One part goes via the pulsation damper with integrated check valve to the aftercooler, where it is cooled down and moisture is separated and evacuated. A second part goes directly to the regeneration area of the heat compression MD dryer.

In the regeneration area of the dryer the hot air regenerates the adsorption drum before passing through the regeneration cooler, where it is cooled down and moisture is separated and evacuated. The cold air coming from the regeneration section is then mixed with the cold air from the aftercooler in the nozzle ejector system before passing through the drying section of the adsorption drum where the moisture is removed. Dry air leaves the compressor through the outlet connection flanges.

Oil flow

The yellow flow is the oil path within the compressor. The oil pump sucks oil from the oil sump and pumps it through the oil cooler and a high efficiency filter to deliver cool, clean oil to the bearings and the gears. The oil then flows back to the gear casing.

Water flow

The dark blue flow represents the water. Water is used in the oil cooler, the intercooler, and the aftercooler, as well as in the integrated dryer.